Sabon zamani na masana'antar kera motoci masu amfani da makamashi yana ɗaukar nauyin manufar sauyi a masana'antu da haɓakawa da kare muhallin yanayi, wanda ke haifar da ci gaban masana'antu na kera kebul masu amfani da wutar lantarki da sauran kayan haɗi masu alaƙa da motocin lantarki, kuma masana'antun kera kebul da hukumomin ba da takardar shaida sun zuba jari mai yawa a cikin bincike da haɓaka kebul masu amfani da wutar lantarki don motocin lantarki. Keyarorin kera motoci masu amfani da wutar lantarki suna da buƙatun aiki mai kyau a kowane fanni, kuma ya kamata su cika ƙa'idodin RoHSb, matakin hana wuta mai ƙarfi na UL94V-0 da aiki mai laushi. Wannan takarda ta gabatar da kayan aiki da fasahar shiri na kebul masu amfani da wutar lantarki don motocin lantarki.

1. Kayan kebul mai ƙarfin lantarki

(1) Kayan jagorar kebul ɗin

A halin yanzu, akwai manyan kayayyaki guda biyu na layin sarrafa kebul: jan ƙarfe da aluminum. Wasu kamfanoni kaɗan suna tunanin cewa tsakiyar aluminum zai iya rage farashin samarwarsu sosai, ta hanyar ƙara jan ƙarfe, ƙarfe, magnesium, silicon da sauran abubuwa bisa ga kayan aluminum tsantsa, ta hanyar hanyoyi na musamman kamar haɗawa da maganin annealing, inganta wutar lantarki, aikin lanƙwasawa da juriyar tsatsa na kebul, don biyan buƙatun ƙarfin kaya iri ɗaya, don cimma irin tasirin da masu sarrafa tsakiya na jan ƙarfe ko ma mafi kyau. Don haka, ana adana kuɗin samarwa sosai. Duk da haka, yawancin kamfanoni har yanzu suna ɗaukar jan ƙarfe a matsayin babban kayan da ke cikin layin sarrafa, da farko, juriyar jan ƙarfe tana da ƙasa, sannan yawancin aikin jan ƙarfe ya fi na aluminum a matakin ɗaya, kamar babban ƙarfin ɗaukar wutar lantarki, ƙarancin asarar wutar lantarki, ƙarancin amfani da makamashi da aminci mai ƙarfi. A halin yanzu, zaɓin masu sarrafa wutar lantarki gabaɗaya yana amfani da masu sarrafa wutar lantarki masu laushi guda 6 na ƙasa (ƙara tsawon wayar jan ƙarfe ɗaya dole ne ya fi 25%, diamita na monofilament ƙasa da 0.30) don tabbatar da laushi da tauri na monofilament na jan ƙarfe. Tebur na 1 ya lissafa ƙa'idodin da dole ne a cika don kayan sarrafa jan ƙarfe da aka saba amfani da su.

(2) Kayan rufin waya na layin kariya

Yanayin cikin motocin lantarki yana da sarkakiya, a gefe guda, wajen zaɓar kayan rufi, don tabbatar da amfani da layin rufi lafiya, a gefe guda kuma, gwargwadon iyawa don zaɓar kayan aiki masu sauƙin sarrafawa da kuma waɗanda ake amfani da su sosai. A halin yanzu, kayan rufi da aka fi amfani da su sune polyvinyl chloride (PVC),polyethylene mai haɗin giciye (XLPE), robar silicone, thermoplastic elastomer (TPE), da sauransu, da manyan kaddarorinsu an nuna su a cikin Jadawali na 2.

Daga cikinsu, PVC tana ɗauke da gubar, amma umarnin RoHS ya hana amfani da gubar, mercury, cadmium, hexvalent chromium, polybrominated diphenyl ethers (PBDE) da polybrominated biphenyls (PBB) da sauran abubuwa masu cutarwa, don haka a cikin 'yan shekarun nan an maye gurbin PVC da XLPE, robar silicone, TPE da sauran kayan da ba su da illa ga muhalli.

(3) Kayan kariya na layin kebul

An raba layin kariya zuwa sassa biyu: layin kariya mai ratsa jiki da kuma layin kariya mai ratsa jiki. Juriyar girman kayan kariya mai ratsa jiki a 20 ° C da 90 ° C da kuma bayan tsufa muhimmin ma'aunin fasaha ne don auna kayan kariya, wanda ke ƙayyade tsawon lokacin aiki na kebul mai ƙarfin lantarki mai ƙarfi a kaikaice. Kayan kariya mai ratsa jiki na ratsa jiki sun haɗa da robar ethylene-propylene (EPR), polyvinyl chloride (PVC), dapolyethylene (PE)kayan da aka gina. Idan kayan ba su da wani amfani kuma ba za a iya inganta matakin inganci a cikin ɗan gajeren lokaci ba, cibiyoyin bincike na kimiyya da masana'antun kayan kebul suna mai da hankali kan binciken fasahar sarrafawa da rabon dabarar kayan kariya, kuma suna neman kirkire-kirkire a cikin rabon abun kariya na kayan kariya don inganta aikin kebul gaba ɗaya.

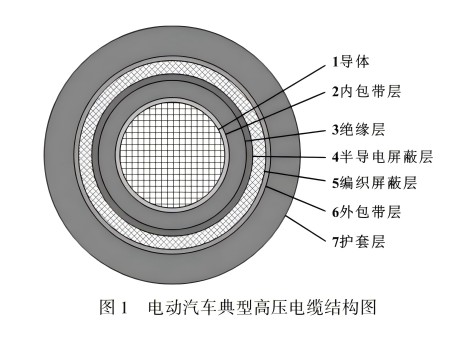

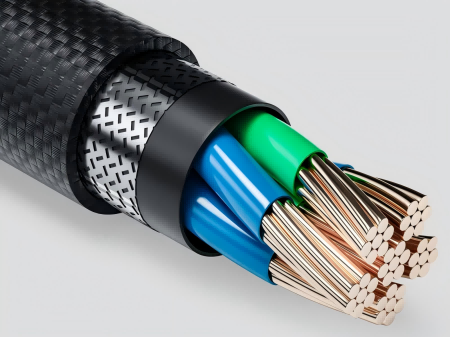

2. Tsarin shirye-shiryen kebul na babban ƙarfin lantarki

(1) Fasahar tuƙin jagora

An daɗe ana ƙirƙiro tsarin kebul na asali, don haka akwai takamaiman bayanai nasu a masana'antu da kamfanoni. A cikin tsarin zana waya, bisa ga yanayin karkatar waya ɗaya, ana iya raba kayan aikin karkatarwa zuwa injin karkatarwa mara juyawa, injin karkatarwa mara juyawa da injin karkatarwa mara juyawa/mara juyawa. Saboda yawan zafin da ke cikin na'urar sarrafa jan ƙarfe, zafin da ke rage zafi da lokaci sun fi tsayi, ya dace a yi amfani da kayan injin karkatarwa mara juyawa don gudanar da ci gaba da jan waya da ci gaba don inganta tsayi da karyewar zane na waya. A halin yanzu, kebul na polyethylene mai haɗin giciye (XLPE) ya maye gurbin kebul na takardar mai gaba ɗaya tsakanin matakan ƙarfin lantarki na 1 zuwa 500kV. Akwai hanyoyin samar da mai jagora guda biyu gama gari ga masu gudanar da XLPE: matsewa mai zagaye da karkatar da waya. A gefe guda, tsakiyar waya na iya guje wa babban zafin jiki da matsin lamba mai yawa a cikin bututun da ke haɗin giciye don matsa kayan kariya da kayan rufi a cikin ramin waya da ya makale kuma ya haifar da ɓarna; A gefe guda kuma, yana iya hana shigar ruwa ta hanyar jagorancin jagora don tabbatar da amincin aikin kebul. Mai gudanar da jan ƙarfe da kansa tsari ne mai haɗa igiyoyi, wanda galibi ana samar da shi ta hanyar injin ɗin ɗaure igiyoyi na yau da kullun, injin ɗin ɗaure igiyoyi na cokali mai yatsu, da sauransu. Idan aka kwatanta da tsarin ɗaure igiyoyi na zagaye, yana iya tabbatar da samuwar mai riƙe igiyoyi na zagaye.

(2) Tsarin samar da rufin kebul na XLPE

Don samar da kebul na XLPE mai ƙarfin lantarki mai yawa, haɗin giciye mai bushewa na catenary (CCV) da haɗin giciye mai bushewa na tsaye (VCV) matakai ne guda biyu na ƙirƙirar.

(3) Tsarin fitarwa

A da, masana'antun kebul sun yi amfani da wani tsari na biyu na fitar da kebul don samar da tushen rufin kebul, mataki na farko a lokaci guda garkuwar mai fitar da kebul da layin rufi, sannan a haɗa su a kan tiren kebul, a sanya su na ɗan lokaci sannan a rufe su da kariyar rufi. A shekarun 1970, wani tsari na fitar da layuka uku na 1+2 ya bayyana a cikin tsakiyar waya mai rufi, wanda ya ba da damar kammala kariyar ciki da waje da kariyar rufi a cikin tsari guda ɗaya. Tsarin da farko yana fitar da kariyar mai juyawa, bayan ɗan gajeren nisa (2~5m), sannan kuma yana fitar da kariyar rufi da kariyar rufi a kan kariyar mai juyawa a lokaci guda. Duk da haka, hanyoyin biyu na farko suna da manyan matsaloli, don haka a ƙarshen shekarun 1990, masu samar da kayan aikin samar da kebul sun gabatar da tsarin samar da kariyar rufi mai layuka uku, wanda ke fitar da kariyar mai juyawa, kariyar rufi da kariyar rufi a lokaci guda. Shekaru da suka gabata, ƙasashen waje sun ƙaddamar da sabon ƙirar kan ganga mai fitar da kaya da farantin raga mai lanƙwasa, ta hanyar daidaita matsin lamba na kwararar ramin kan sukurori don rage tarin kayan aiki, tsawaita lokacin samarwa akai-akai, maye gurbin canjin ƙayyadaddun ƙayyadaddun ƙira na ƙirar kai wanda hakan zai iya adana farashi mai yawa na lokacin aiki da inganta inganci.

3. Kammalawa

Sabbin motocin makamashi suna da kyakkyawan damar haɓakawa da kuma babbar kasuwa, suna buƙatar jerin samfuran kebul masu ƙarfin lantarki mai ƙarfi tare da ƙarfin kaya mai yawa, juriya mai zafi, tasirin kariyar lantarki, juriya mai lanƙwasa, sassauci, tsawon rai na aiki da sauran kyakkyawan aiki a cikin samarwa kuma suna mamaye kasuwa. Kayan kebul masu ƙarfin lantarki mai ƙarfin lantarki da tsarin shirya su suna da fa'idodi masu yawa na haɓakawa. Motar lantarki ba za ta iya inganta ingancin samarwa ba kuma ta tabbatar da amfani da aminci ba tare da kebul mai ƙarfin lantarki mai yawa ba.

Lokacin Saƙo: Agusta-23-2024