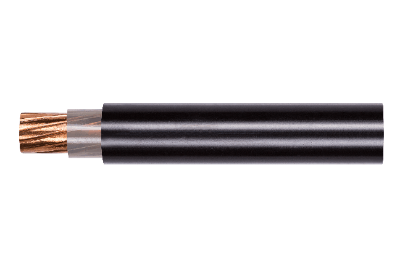

Ana amfani da polyethylene (PE) sosai a cikin samar da wutar lantarkirufin da kuma rufin kebul na wutar lantarki da kebul na sadarwasaboda ƙarfin injina mai kyau, tauri, juriyar zafi, rufin gida, da kuma daidaiton sinadarai. Duk da haka, saboda halayen tsarin PE da kanta, juriyarsa ga fashewar damuwa ta muhalli ba ta da kyau. Wannan matsalar ta fi bayyana musamman lokacin da aka yi amfani da PE a matsayin murfin waje na manyan kebul masu sulke.

1. Tsarin Fasawar Sheath ta PE

Fashewar murfin PE galibi yana faruwa ne a yanayi biyu:

a. Fashewar Damuwa a Muhalli: Wannan yana nufin abin da ke faruwa inda murfin ke fuskantar tsagewa mai rauni daga saman saboda matsin lamba ko fallasa ga kafofin watsa labarai na muhalli bayan shigarwa da aiki da kebul. Yawanci yana faruwa ne sakamakon damuwa ta ciki a cikin murfin da kuma tsawaita lokacin fallasa ga ruwa mai ƙarfi. Bincike mai zurfi kan gyaran kayan ya magance wannan nau'in tsagewa sosai.

b. Fashewar Matsala ta Inji: Wannan yana faruwa ne saboda ƙarancin tsari a cikin kebul ko kuma hanyoyin fitar da murfin da bai dace ba, wanda ke haifar da yawan damuwa da fashewar da ke haifar da nakasa yayin shigar da kebul. Wannan nau'in fashewa ya fi bayyana a cikin murfin waje na manyan kebul na ƙarfe masu sulke.

2. Dalilan Fashewa da Matakan Ingantawa na PE

2.1 Tasirin KebulTef ɗin KarfeTsarin gini

A cikin kebul masu girman diamita na waje, layin sulke yawanci yana ƙunshe da naɗe tef ɗin ƙarfe mai layuka biyu. Dangane da diamita na waje na kebul, kauri tef ɗin ƙarfe ya bambanta (0.2mm, 0.5mm, da 0.8mm). Tef ɗin ƙarfe masu kauri suna da ƙarfi mafi girma da ƙarancin laushi, wanda ke haifar da ƙarin tazara tsakanin saman da ƙasan layuka. A lokacin fitarwa, wannan yana haifar da bambance-bambance masu mahimmanci a cikin kauri na sheath tsakanin saman da ƙasan layukan sulke na saman Layer ɗin sulke. Yankunan sirara na sheath a gefun tef ɗin ƙarfe na waje suna fuskantar mafi girman yawan damuwa kuma sune manyan wuraren da fashewar nan gaba ke faruwa.

Domin rage tasirin tef ɗin ƙarfe mai sulke akan murfin waje, ana naɗe ko kuma a fitar da wani Layer mai kauri tsakanin tef ɗin ƙarfe da murfin PE. Wannan Layer mai sulke ya kamata ya zama mai kauri iri ɗaya, ba tare da wrinkles ko buɗaɗɗen abu ba. Ƙara Layer mai sulke yana inganta santsi tsakanin layukan tef ɗin ƙarfe guda biyu, yana tabbatar da kauri ɗaya na tef ɗin PE, kuma, tare da matsewar murfin PE, yana rage damuwa ta ciki.

ONEWORLD yana bawa masu amfani da kauri daban-daban nakayan sulke na tef ɗin ƙarfe na galvanizeddon biyan buƙatu daban-daban.

2.2 Tasirin Tsarin Samar da Kebul

Babban matsalolin da ke tattare da tsarin fitar da manyan murfin kebul na waje masu sulke sune rashin isasshen sanyaya, rashin ingantaccen shiri na mold, da kuma yawan mikewa, wanda ke haifar da matsanancin damuwa a cikin murfin. Manyan kebul, saboda kauri da fadi na murfinsu, galibi suna fuskantar iyaka a cikin tsayi da girman ramukan ruwa akan layukan samar da fitarwa. Sanyaya daga sama da digiri 200 na Celsius yayin fitarwa zuwa zafin ɗaki yana haifar da ƙalubale. Rashin isasshen sanyaya yana haifar da murfin da ya yi laushi kusa da layin sulke, yana haifar da karce a saman murfin lokacin da aka naɗe kebul, wanda daga ƙarshe ke haifar da tsagewa da karyewa yayin shimfiɗa kebul saboda ƙarfin waje. Bugu da ƙari, rashin isasshen sanyaya yana taimakawa wajen ƙaruwar ƙarfin raguwar ciki bayan naɗewa, yana haɓaka haɗarin fashewar murfin a ƙarƙashin manyan ƙarfin waje. Don tabbatar da isasshen sanyaya, ana ba da shawarar ƙara tsayi ko girman ramukan ruwa. Rage saurin fitarwa yayin da ake kula da ingantaccen filastik na murfin da kuma ba da isasshen lokaci don sanyaya yayin naɗewa yana da mahimmanci. Bugu da ƙari, la'akari da polyethylene a matsayin polymer mai lu'ulu'u, hanyar sanyaya zafin jiki ta raba-raba, daga 70-75°C zuwa 50-55°C, kuma a ƙarshe zuwa zafin ɗaki, yana taimakawa wajen rage damuwa a cikin jiki yayin aikin sanyaya.

2.3 Tasirin Radius Mai Layi akan Layi na Kebul

A lokacin naɗa kebul, masana'antun suna bin ƙa'idodin masana'antu don zaɓar kebul na isar da sako masu dacewa. Duk da haka, daidaita tsayin isar da sako masu tsayi ga manyan kebul na waje yana haifar da ƙalubale wajen zaɓar kebul na isar da sako masu dacewa. Don cika takamaiman tsayin isar da sako, wasu masana'antun suna rage diamita na ganga na juyawa, wanda ke haifar da rashin isasshen radii na lanƙwasa don kebul. Lanƙwasawa da yawa yana haifar da ƙaura a cikin yadudduka na sulke, yana haifar da ƙarfin yankewa mai yawa akan murfin. A cikin mawuyacin hali, burrs na bakin ƙarfe na iya huda layin matashin kai, yana saka kai tsaye cikin murfin kuma yana haifar da tsagewa ko tsagewa a gefen layin ƙarfe. A lokacin shimfiɗa kebul, lanƙwasawa da jan ƙarfe suna sa murfin ya fashe tare da waɗannan tsagewar, musamman ga kebul na kusa da layukan ciki na reel, wanda ke sa su zama masu sauƙin karyewa.

2.4 Tasirin Muhalli na Gine-gine da Shigarwa a Wurin Aiki

Domin daidaita tsarin kebul, ana ba da shawarar a rage saurin sanya kebul, a guji matsin lamba mai yawa a gefe, lanƙwasawa, ƙarfin jan kebul, da kuma karo a saman, don tabbatar da yanayin gini mai wayewa. Zai fi kyau, kafin a shigar da kebul, a bar kebul ya huta a 50-60°C don sakin damuwa ta ciki daga murfin. A guji ɗaukar igiyoyi na dogon lokaci zuwa hasken rana kai tsaye, domin yanayin zafi daban-daban a ɓangarori daban-daban na kebul na iya haifar da yawan damuwa, wanda ke ƙara haɗarin fashewa a lokacin shimfiɗa kebul.

Lokacin Saƙo: Disamba-18-2023