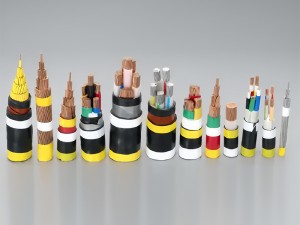

Tsarin kebul ɗin yana da sauƙi, a gaskiya ma, kowane ɓangarensa yana da nasa muhimmin manufa, don haka dole ne a zaɓi kowane kayan haɗin a hankali lokacin ƙera kebul ɗin, don tabbatar da ingancin kebul ɗin da aka yi da waɗannan kayan yayin aiki.

1. Kayan jagora

A tarihi, kayan da ake amfani da su wajen sarrafa kebul na wutar lantarki sune tagulla da aluminum. An kuma gwada sodium na ɗan lokaci. Tagulla da aluminum suna da ingantaccen watsa wutar lantarki, kuma adadin tagulla yana da ƙarancin yawa lokacin da ake watsa wutar lantarki iri ɗaya, don haka diamita na waje na jagorar jan ƙarfe ya fi na jagorar aluminum ƙanƙanta. Farashin aluminum ya fi ƙasa da tagulla. Bugu da ƙari, saboda yawan jan ƙarfe ya fi na aluminum girma, koda kuwa ƙarfin ɗaukar wutar lantarki iri ɗaya ne, ɓangaren giciye na jagorar aluminum ya fi na jagorar jan ƙarfe girma, amma kebul na jagorar aluminum har yanzu ya fi na kebul na jagorar jan ƙarfe sauƙi.

2. Kayan rufi

Akwai kayan rufi da yawa da kebul na wutar lantarki na MV zai iya amfani da su, har ma da kayan rufi na takarda da aka yi wa ado da fasaha, waɗanda aka yi amfani da su cikin nasara fiye da shekaru 100. A yau, rufin polymer da aka fitar ya sami karbuwa sosai. Kayan rufi na polymer da aka fitar sun haɗa da PE (LDPE da HDPE), XLPE, WTR-XLPE da EPR. Waɗannan kayan thermoplastic ne da kuma thermosetting. Kayan thermoplastic suna lalacewa lokacin da aka dumama su, yayin da kayan thermoset ke riƙe da siffarsu a yanayin zafi mai aiki.

2.1. Rufe takarda

A farkon aikinsu, kebul masu rufe takarda suna ɗaukar ƙaramin kaya kawai kuma ana kula da su sosai. Duk da haka, masu amfani da wutar lantarki suna ci gaba da yin kebul ɗin yana ɗaukar ƙarin kaya mai yawa, yanayin amfani na asali ba ya dace da buƙatun kebul na yanzu, to kyakkyawan ƙwarewar asali ba zai iya wakiltar aikin kebul na gaba ba dole ne ya kasance mai kyau. A cikin 'yan shekarun nan, ba a cika amfani da kebul masu rufe takarda ba.

2.2.PVC

Har yanzu ana amfani da PVC a matsayin kayan rufewa ga kebul na 1kV mai ƙarancin wutar lantarki kuma kayan rufewa ne. Duk da haka, ana maye gurbin amfani da PVC a cikin rufin kebul da XLPE cikin sauri, kuma ana maye gurbin amfani da shi a cikin murfin da sauri da polyethylene mai ƙarancin yawa (LLDPE), polyethylene mai matsakaicin yawa (MDPE) ko polyethylene mai yawan yawa (HDPE), da kebul na waɗanda ba PVC ba suna da ƙarancin farashin zagayowar rayuwa.

2.3. Polyethylene (PE)

An ƙirƙiro polyethylene mai ƙarancin yawa (LDPE) a cikin shekarun 1930 kuma yanzu ana amfani da shi azaman resin tushe don polyethylene mai haɗin gwiwa (XLPE) da kayan polyethylene mai haɗin gwiwa na bishiyoyi (WTR-XLPE) masu jure ruwa. A yanayin thermoplastic, matsakaicin zafin aiki na polyethylene shine 75 ° C, wanda ya yi ƙasa da zafin aiki na kebul na takarda mai rufi (80 ~ 90 ° C). An magance wannan matsalar tare da zuwan polyethylene mai haɗin gwiwa (XLPE), wanda zai iya haɗuwa ko wuce zafin sabis na kebul mai rufi na takarda.

2.4.Polyethylene mai haɗin giciye (XLPE)

XLPE wani abu ne da ake amfani da shi wajen daidaita yanayin zafi ta hanyar haɗa polyethylene mai ƙarancin yawa (LDPE) da wani abu mai haɗa haɗin gwiwa (kamar peroxide).

Matsakaicin zafin aiki na na'urar sarrafa kebul mai rufe XLPE shine 90 ° C, gwajin ɗaukar nauyi yana zuwa 140 ° C, kuma zafin da'irar gajere na iya kaiwa 250 ° C. XLPE yana da kyawawan halaye na dielectric kuma ana iya amfani da shi a cikin kewayon ƙarfin lantarki na 600V zuwa 500kV.

2.5. Itace mai jure ruwa Polyethylene mai alaƙa da juna (WTR-XLPE)

Lamarin bishiyoyin ruwa zai rage tsawon rayuwar kebul na XLPE. Akwai hanyoyi da yawa don rage girman bishiyoyin ruwa, amma ɗaya daga cikin abubuwan da aka fi yarda da su shine amfani da kayan kariya na musamman waɗanda aka ƙera don hana girman bishiyoyin ruwa, wanda ake kira polyethylene mai haɗin gwiwa na itace mai jure ruwa WTR-XLPE.

2.6. Robar Ethylene propylene (EPR)

EPR wani abu ne da ke saita zafi wanda aka yi da ethylene, propylene (wani lokacin monomer na uku), kuma copolymer na monomers guda uku ana kiransa ethylene propylene diene roba (EPDM). A cikin kewayon zafin jiki mai faɗi, EPR koyaushe yana da laushi kuma yana da kyakkyawan juriya ga corona. Duk da haka, asarar dielectric na kayan EPR ya fi na XLPE da WTR-XLPE girma sosai.

3. Tsarin rufewa da ƙura

Tsarin haɗakarwa ya keɓance ga polymer ɗin da aka yi amfani da shi. Ƙirƙirar polymers masu haɗin gwiwa yana farawa da matrix polymer sannan a ƙara masu daidaita abubuwa da masu haɗin gwiwa don samar da cakuda. Tsarin haɗakarwa yana ƙara ƙarin wuraren haɗi zuwa tsarin kwayoyin halitta. Da zarar an haɗa, sarkar kwayoyin polymer ta kasance mai laushi, amma ba za a iya raba ta gaba ɗaya zuwa narkewar ruwa ba.

4. Kariyar mai jagora da kayan kariya

Ana fitar da layin kariya mai ɗaukar hoto mai ɗaukar hoto a saman waje na mai jagora da kuma rufin don daidaita filin lantarki da kuma ɗaukar filin lantarki a cikin tsakiyar kebul ɗin da aka rufe. Wannan kayan yana ɗauke da matakin injiniya na kayan baƙar carbon don ba da damar layin kariya na kebul ya sami daidaiton juyi a cikin kewayon da ake buƙata.

Lokacin Saƙo: Afrilu-12-2024