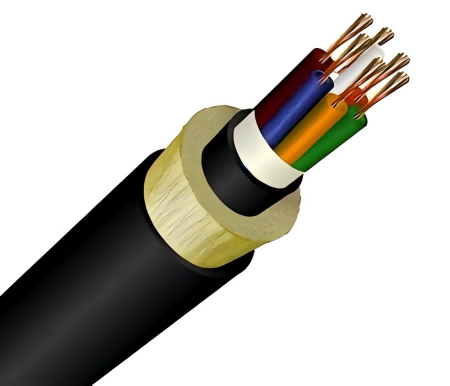

Domin tabbatar da cewa an kare tsakiyar kebul na gani daga lalacewar injiniya, zafi, sinadarai, da danshi, dole ne a sanya masa wani rufi ko ma ƙarin yadudduka na waje. Waɗannan matakan suna tsawaita rayuwar zare masu gani yadda ya kamata.

Shafunan da aka fi amfani da su a cikin kebul na gani sun haɗa da shafunan A (shafunan da aka haɗa da aluminum-polyethylene), shafunan S (shafunan da aka haɗa da ƙarfe-polyethylene), da shafunan polyethylene. Ga kebul na gani mai zurfi, yawanci ana amfani da shafunan ƙarfe da aka rufe.

Ana yin rufin polyethylene ne daga layin da ke da ƙarancin yawa, matsakaici, ko kuma layin da ke da ƙarancin yawa.babban yawan kayan polyethylene baƙi, wanda ya yi daidai da ƙa'idar GB/T15065. Ya kamata saman murfin polyethylene mai baƙi ya zama santsi kuma iri ɗaya, ba tare da kumfa, ramukan filaye, ko tsagewa ba. Idan aka yi amfani da shi azaman murfin waje, kauri na asali ya kamata ya zama 2.0 mm, tare da mafi ƙarancin kauri na 1.6 mm, kuma matsakaicin kauri akan kowane sashe bai kamata ya zama ƙasa da 1.8 mm ba. Halayen injiniya da na zahiri na murfin ya kamata su cika buƙatun da aka ƙayyade a cikin YD/T907-1997, Tebur 4.

A-sheath ya ƙunshi wani Layer na shingen danshi da aka yi da naɗewa a tsayi kuma an rufe shi da wani abu mai kama da na'urar.Tef ɗin aluminum mai rufi na filastik, tare da murfin polyethylene baƙi mai fitarwa. Kurmin polyethylene yana ɗaure da tef ɗin haɗin gwiwa da gefunan tef ɗin da ke haɗuwa, wanda za a iya ƙara ƙarfafa shi da manne idan ana buƙata. Faɗin tarko na tef ɗin haɗin gwiwa bai kamata ya zama ƙasa da mm 6 ba, ko kuma ga tsakiyar kebul waɗanda diamitansu bai kai mm 9.5 ba, bai kamata ya zama ƙasa da kashi 20% na kewayen tsakiyar ba. Kauri na tarko na polyethylene shine 1.8 mm, tare da mafi ƙarancin kauri na mm 1.5, kuma matsakaicin kauri ba ƙasa da mm 1.6 ba. Ga yadudduka na waje na Type 53, kauri na tarko shine 1.0 mm, mafi ƙarancin kauri shine 0.8 mm, kuma matsakaicin kauri shine mm 0.9. Tef ɗin haɗin aluminum-plastic ya kamata ya dace da ma'aunin YD/T723.2, tare da tef ɗin aluminum yana da kauri na lamba 0.20 mm ko 0.15 mm (mafi ƙarancin 0.14 mm) da kauri na fim ɗin haɗin gwiwa na 0.05 mm.

Ana ba da izinin haɗa wasu tef ɗin haɗin kai yayin ƙera kebul, muddin tazarar haɗin gwiwa ba ta ƙasa da mita 350 ba. Waɗannan haɗin dole ne su tabbatar da ci gaba da amfani da wutar lantarki da kuma dawo da layin filastik ɗin haɗin kai. Ƙarfin haɗin gwiwa bai kamata ya zama ƙasa da kashi 80% na ƙarfin tef ɗin na asali ba.

S-sheath yana amfani da wani Layer na shingen danshi da aka yi da corrugated mai tsayi da kuma rufewaTef ɗin ƙarfe mai rufi na filastik, tare da murfin polyethylene baƙi mai fitarwa. Kurmin polyethylene yana ɗaure da tef ɗin haɗin gwiwa da gefunan tef ɗin da ke haɗuwa, wanda za a iya ƙarfafa shi da manne idan ya cancanta. Tef ɗin haɗin gwiwa ya kamata ya samar da tsari kamar zobe bayan naɗewa. Faɗin haɗin gwiwa bai kamata ya zama ƙasa da mm 6 ba, ko kuma ga tsakiyar kebul waɗanda diamitansu bai kai mm 9.5 ba, ya kamata ya zama bai gaza kashi 20% na kewayen tsakiya ba. Kauri na musamman na murfin polyethylene shine mm 1.8, tare da mafi ƙarancin kauri na mm 1.5, kuma matsakaicin kauri bai gaza mm 1.6 ba. Tef ɗin haɗin gwiwa na ƙarfe-roba ya kamata ya dace da ma'aunin YD/T723.3, tare da tef ɗin ƙarfe yana da kauri na musamman na mm 0.15 (mafi ƙarancin 0.13 mm) da kauri na fim ɗin haɗin gwiwa na mm 0.05.

Ana ba da izinin haɗa tef ɗin haɗin gwiwa yayin ƙera kebul, tare da mafi ƙarancin tazara tsakanin haɗin gwiwa na mita 350. Ya kamata tef ɗin ƙarfe ya kasance a haɗe da duwawu, yana tabbatar da ci gaba da lantarki da kuma dawo da layin haɗin gwiwa. Ƙarfin da ke kan haɗin gwiwa bai kamata ya zama ƙasa da kashi 80% na ƙarfin tef ɗin haɗin gwiwa na asali ba.

Tef ɗin aluminum, tef ɗin ƙarfe, da kuma sulke na ƙarfe da ake amfani da su don shingen danshi dole ne su ci gaba da kasancewa da wutar lantarki a tsawon kebul ɗin. Ga murfin da aka haɗa (gami da layukan waje na Type 53), ƙarfin barewar da ke tsakanin tef ɗin aluminum ko ƙarfe da murfin polyethylene, da kuma ƙarfin barewar da ke tsakanin gefunan da ke rufe tef ɗin aluminum ko ƙarfe, bai kamata ya zama ƙasa da 1.4 N/mm ba. Duk da haka, lokacin da aka shafa kayan toshe ruwa ko shafi a ƙarƙashin tef ɗin aluminum ko ƙarfe, ba a buƙatar ƙarfin barewar a gefunan da ke rufewa.

Wannan cikakken tsarin kariya yana tabbatar da dorewa da amincin kebul na gani a wurare daban-daban, yana biyan buƙatun tsarin sadarwa na zamani yadda ya kamata.

Lokacin Saƙo: Janairu-20-2025