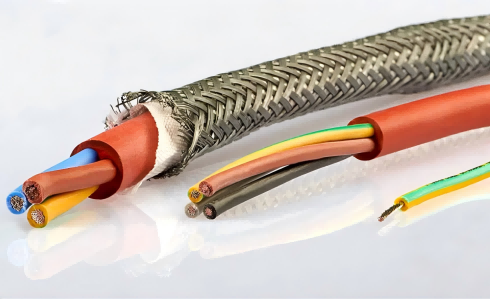

Kebulan da ke jure zafi mai yawa suna nufin kebul na musamman waɗanda za su iya kiyaye aikin lantarki da na inji mai ɗorewa a cikin yanayin zafi mai yawa. Ana amfani da su sosai a fannin sufurin jiragen sama, sararin samaniya, man fetur, narkar da ƙarfe, sabon makamashi, masana'antar soja, da sauran fannoni.

Kayan da ake amfani da su wajen kera kebul masu jure zafi mai yawa sun haɗa da kayan sarrafawa, kayan rufewa, da kayan rufewa. Daga cikinsu, mai kula da na'urar ya kamata ya sami kyakkyawan juriya da juriya ga zafi mai yawa; layin rufewa yana buƙatar samun halaye kamar juriya ga zafi mai yawa, juriya ga lalacewa, da juriya ga lalata sinadarai; murfin ya kamata ya ƙunshi ayyuka kamar juriya ga zafi mai yawa, juriya ga tsufa, juriya ga mai, da kariyar inji.

Ana yin amfani da na'urar sarrafa kebul masu jure zafi mai yawa da tagulla ko aluminum, wadda aka zana ta cikin wayoyi masu diamita daban-daban ta hanyar injin zana waya. A lokacin aikin zane, dole ne a sarrafa sigogi kamar saurin zane, zafin mold, da zafin sanyaya don tabbatar da santsi a saman da kuma halayen injina na wayoyin sun cika buƙatun.

Layin rufi muhimmin sashi ne na kebul masu jure zafi mai yawa, kuma tsarin shirya shi yana shafar aikin kebul ɗin kai tsaye. Ana amfani da kayan polymer kamar polytetrafluoroethylene (PTFE), ethylene propylene mai fluorinated (FEP), polyether ether ketone (PEEK), ko robar silicone ta yumbu don samar da layin rufi ta hanyar fitar da iska ko tsarin ƙera shi. A lokacin wannan tsari, dole ne a sarrafa zafin jiki, matsin lamba, da saurin layin samarwa daidai don tabbatar da cewa layin rufi yana da kauri iri ɗaya, babu lahani, da kuma aikin rufin lantarki mai karko.

Murfin yana aiki a matsayin layin kariya na waje na kebul, wanda aka fi amfani da shi don kariya daga lalacewar injiniya da kuma mummunan zaizayar muhalli. Kayan da aka fi amfani da su wajen rufewa sun haɗa da polyvinyl chloride (PVC), polyethylene (PE),polyethylene mai haɗin giciye (XLPE), da kuma na musamman na fluoroplastics. A lokacin aikin gyaran firinta, dole ne a kula da zafin fitar da iska, matsin kan kai, da kuma saurin jan hankali sosai don tabbatar da cewa murfin yana da kauri, daidai gwargwado, kuma yana da santsi.

Dole ne a kula da waɗannan muhimman abubuwan yayin aikin samarwa don tabbatar da ingancin kebul ɗin da aka gama:

1. Kula da Zafin Jiki: Dole ne a sarrafa zafin jiki daidai a kowane matakin tsari don tabbatar da aikin abu da kwanciyar hankali na tsari.

2. Kula da Matsi: Dole ne a sarrafa matsi yadda ya kamata yayin fitarwa ko ƙera shi don tabbatar da kauri da ingancin rufin da murfin.

3. Sarrafa Sauri: Dole ne a sarrafa saurin waya sosai yayin aiwatarwa kamar zane da fitarwa don tabbatar da ingancin samarwa da daidaiton samfur.

4. Maganin Busarwa: Wasu kayan polymer suna buƙatar busarwa kafin a busar da su don guje wa lahani kamar kumfa yayin sarrafawa.

5. Duba Inganci: Dole ne a yi bincike mai tsauri a lokacin samarwa da kuma bayan kammala samfurin, gami da duba yanayinsa, auna girma, gwajin aikin lantarki, da gwaje-gwajen tsufa mai zafi, don tabbatar da cewa samfurin ya cika ƙa'idodi da buƙatun amfani.

Samar da kebul masu jure zafi mai yawa ya ƙunshi matakai da yawa daidai, kuma dole ne a aiwatar da cikakken tsarin kula da inganci don samun samfuran da suka cancanta. Ta hanyar ƙwarewa sosai kan zaɓin kayan masarufi, daidaita sigogin tsari, da kuma sarrafa tsarin masana'antu, ingancin samarwa da daidaiton samfura na kebul za a iya inganta su sosai. Bugu da ƙari, haɓaka sabbin abubuwa na fasaha da haɓaka kayan aiki, gabatar da layukan samarwa ta atomatik da tsarin gano abubuwa masu hankali, zai ƙara haɓaka ingancin samarwa da gasa a masana'antu, yana buɗe faffadan damar ci gaba don kera kebul masu jure zafi mai yawa.

A matsayina na ƙwararriyar mai samar da kayan kebul,DUNIYA ƊAYAKullum tana da niyyar samar wa abokan cinikin duniya ingantattun hanyoyin samar da kebul. Tsarin samfurin kamfanin ya haɗa da kayan aiki na musamman da aka ambata a cikin labarin, kamar su polyvinyl chloride (PVC), polyethylene mai haɗin giciye (XLPE), polytetrafluoroethylene (PTFE), da kuma kaset masu aiki kamar Mylar Tape, Water Blocking Tepe, da Semi-conductive Water Blocking Tepe, da kayan kebul na gani masu inganci kamar PBT, FRP, da Aramid Yarn. Muna bin sabbin fasahohi a matsayin injin haɓakawa, muna ci gaba da inganta dabarun kayan aiki da hanyoyin samarwa don samar wa abokan ciniki cikakken kewayon samfura tare da kyakkyawan aiki da inganci mai ɗorewa, yana taimaka wa kamfanonin kera kebul haɓaka gasa da haɓaka ci gaban fasaha da haɓaka sabbin abubuwa na masana'antar kebul.

Lokacin Saƙo: Satumba-19-2025