1. Kebul ɗin Mica mai rufi da aka yi da murhu mai rufi da jan ƙarfe

An yi amfani da kebul na roba mai rufi da murhu na Mica tef, wanda aka yi da na'urar sarrafa tagulla, da kuma na'urar haɗa tagulla mai rufi da murhu, tare da kyakkyawan aikin wuta, tsawon tsayi mai tsawo, ƙarfin ɗaukar kaya, da kuma ingantaccen tattalin arziki da sauransu.

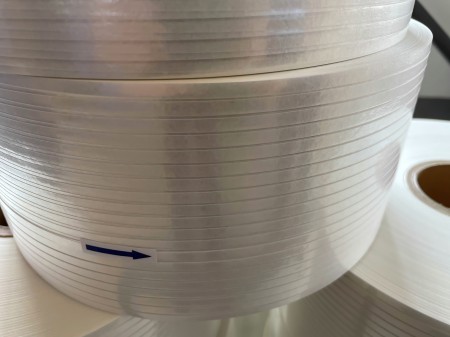

Tsarin kera kebul na roba mai rufi da aka yi da tagulla mai rufi da tef ɗin mica yana farawa da ci gaba da zubar da waya ta tagulla ko sandar jan ƙarfe, an murƙushe igiyoyi da yawa na wayar jan ƙarfe, kuma an naɗe jagorar da ƙarfin zafin jiki mai ƙarfi.tef ɗin mica na roba(ana iya amfani da tef ɗin mica mai ƙamshi don samfuran da ba su da halogen, ƙarancin hayaƙi da ƙarancin guba), ana cika layin rufin da zare na gilashi mara alkali, kuma ana naɗe kebul ɗin da tef ɗin mica na roba mai jure zafi mai yawa don samar da Layer mai kariya. Ana haɗa murfin jan ƙarfe a cikin bututun jan ƙarfe bayan an naɗe tef ɗin jan ƙarfe, sannan a samar da shi ta hanyar ci gaba da birgima mai lanƙwasa. Ba za a iya fallasa takamaiman buƙatun murfin ƙarfe ba, kuma ana iya ƙara Layer na polyolefin (ƙarancin hayaƙi mara halogen) a waje.

Idan aka kwatanta da kebul na magnesium oxide, samfuran kebul na mica tef mai rufi da aka rufe da jan ƙarfe, ban da aikin wuta yana kusa, zai iya cimma tsayin da ya ci gaba, a cikin 95 mm² kuma ana iya yin su zuwa kebul na rukuni mai yawa, don shawo kan gazawar manyan haɗin kebul. Duk da haka, walda mai rufi da bututun jan ƙarfe yana da sauƙin fashewa, nakasar fitarwa da kuma rufin mica guda ɗaya, wanda kuma ya zama lahani na tsarin haihuwa, kuma buƙatar ƙarfin aikin shigarwa har yanzu yana da girma sosai.

Wurin sarrafawa na kebul mai rufi da aka yi da tagulla mai rufi da aka yi da tagulla mai rufi da aka yi da tagulla shine zaɓin kayan bel ɗin mica mai zafi da kuma tsarin walda da birgima na kebul mai rufi da tagulla. Zaɓin kayan tef ɗin mica mai zafi yana shafar aikin kariya daga wuta na samfurin kai tsaye. Yawan tef ɗin mica zai haifar da ɓatar da kayan, kuma ƙarancin ba zai cimma aikin kariya daga wuta ba. Idan walda na jaket ɗin tagulla ba shi da ƙarfi, walda na bututun tagulla mai rufi yana da sauƙin fashewa, a lokaci guda, zurfin birgima shi ma mabuɗin sarrafa tsari, bambancin zurfin birgima da kuma zurfin jaket ɗin tagulla zai haifar da bambanci a ainihin yankin giciye na jaket ɗin tagulla, don haka yana shafar juriyar jaket ɗin tagulla.

2. Kebul mai hana ruwa roba na silicone (ma'adinai) mai rufi

Roba ta silicone ta yumbuKebul mai jure wa wuta mai ma'adinai sabon nau'in kebul ne mai jure wa wuta, rufinsa da iskar oxygen ɗinsa suna amfani da kayan haɗin roba na silicone na yumbu, kayan suna da laushi kamar robar silicone ta yau da kullun a ƙarƙashin yanayin zafin jiki na yau da kullun, kuma za su samar da harsashi mai tauri na yumbu a ƙarƙashin yanayin zafin jiki mai zafi na 500 ℃ ko sama da haka. A lokaci guda, ana kiyaye aikin rufin, kuma layin kebul ɗin zai iya ci gaba da aiki na yau da kullun na wani lokaci idan gobara ta tashi, don taimakawa aikin ceto da rage asarar rayuka da dukiyoyi gwargwadon iko.

Kebul ɗin roba mai rufi da ma'adinai mai rufi da aka rufe da roba mai rufi da wani Layer mai hana ruwa (abin da aka haɗa da robar silicone na yumbu) wanda aka yi amfani da shi a matsayin mai gudanarwa na kebul, tsakanin tsakiyar kebul ɗin ana samar da Layer ɗin cikawa mai jure zafi mai yawa, kamar kayan haɗin roba na silicone na yumbu, da ƙarin Layer mai kariya, bayyanar kebul ɗin don layin murfin waje. Wannan nau'in samfurin yana da alaƙa da Layer ɗin hana ruwa mai jure zafi wanda aka yi da robar silicone mai hana ruwa mai yumbu, kuma harsashi mai tauri da aka samar bayan cirewa har yanzu yana da rufin lantarki, wanda zai iya kare layukan watsawa da rarrabawa daga yashewar harshen wuta, don tabbatar da kwararar wutar lantarki da sadarwa mai kyau, da kuma samun lokacin ceto mai mahimmanci don fitarwa da ceto ma'aikata idan gobara ta tashi. Kayayyakin hana wuta na yumbu galibi sun haɗa da robar silicone mai hana wuta mai yumbu, tef ɗin haɗin wuta mai hana wuta mai yumbu da igiyar cika wuta mai yumbu.

Robar silicone ta yumbu a zafin ɗaki ba ta da guba, ba ta da ɗanɗano, tana da laushi da laushi, a yanayin zafi sama da 500 ° C, abubuwan da ke cikinta na halitta cikin ɗan gajeren lokaci sun zama abu mai tauri kamar yumbu, samar da kyakkyawan layin kariya daga iska, kuma tare da haɓakar lokacin ƙonewa, ƙaruwar zafin jiki, taurinsa ya fi bayyana. Robar silicone mai rufi kuma tana da kyawawan halaye na asali kuma ana iya aiwatar da ita a cikin layukan samar da iskar gas na yau da kullun. Gibin da rufin kebul ɗin roba ne mai rufi, wanda ke toshe iskar oxygen, kuma ana amfani da murfin sulke mai haɗawa don ƙirƙirar murfin bututun maciji mai sassauƙa, wanda zai iya jure matsin lamba na radial da kare kebul daga lalacewar injiniya ta waje.

Babban wuraren sarrafawa na tsarin samar da kebul na roba na silicone mai rufi da ma'adinai galibi yana cikin tsarin vulcanization da haɗin gwiwa na robar silicone na yumbu.

Robar silicone ta yumbu tana cikin babban kayan robar silicone mai zafi (HTV), wato, robar silicone ta methyl vinyl 110-2 da aka ƙara kamar farin carbon black, man silicone, foda na porcelain da sauran ƙari bayan haɗawa sannan a ƙara ta a cikin injin vulcanization sau biyu 24, wanda ba a iya cire shi don farin manna mai ƙarfi, mara kyawun tsari, yana buƙatar zafin extruder don kiyaye wani ƙaramin zafin jiki, da zarar ya fi wannan zafin. Za a sami wani abu na manne mai cikakke, wanda ke haifar da degumming da lalata layin rufi. Bugu da ƙari, saboda rashin ƙarfi na robar silicone ta yumbu, ba za a iya ɗaukar shi ta hanyar sukurori zuwa cikin manne ba, wanda ke haifar da gibin kayan manne a cikin sukurori, wanda kuma zai haifar da al'amarin degumming. Domin guje wa matsalolin da ke sama, yadda ake saita kayan aikin da suka dace don extruder, yadda ake kula da yanayin ƙarancin zafin extruder, da kuma yadda ake yin robar a cikin sukurori ba tare da gibba ba sun zama mabuɗin tabbatar da ingancin layin rufi.

Ana samar da sulke mai haɗa kai ta hanyar bututu mai karkace tare da ƙugiya mara daidaito. Saboda haka, a cikin samarwa, yadda ake saita jerin molds masu dacewa bisa ga takamaiman bayanai, faɗi da kauri na tsiri da ake amfani da shi don sulke mai haɗa kai sune mabuɗin haifar da matsalolin tsari kamar rashin maƙulli mai matsewa.

Lokacin Saƙo: Oktoba-23-2024