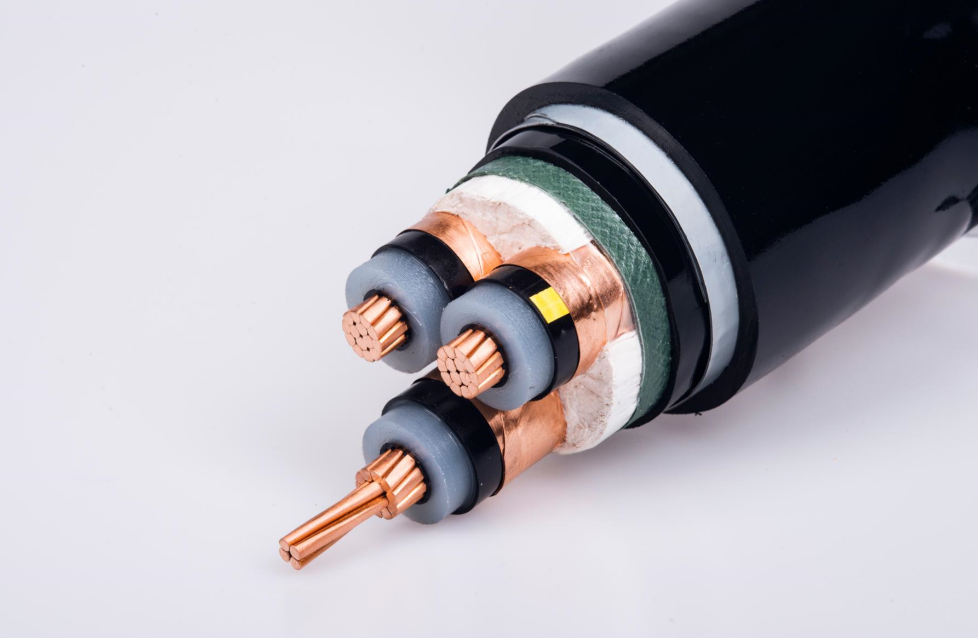

Tsarin kariya na ƙarfe tsari ne mai mahimmanci a cikinkebul na wutar lantarki mai rufi da polyethylene mai matsakaicin ƙarfin lantarki (3.6/6kV∽26/35kV)Tsarin tsarin garkuwar ƙarfe yadda ya kamata, ƙididdige ƙarfin lantarki na ɗan gajeren zangon da garkuwar za ta ɗauka daidai, da kuma haɓaka dabarar sarrafa garkuwa mai ma'ana suna da matuƙar muhimmanci don tabbatar da ingancin kebul masu haɗin gwiwa da kuma amincin tsarin aiki gaba ɗaya.

Tsarin Kariya:

Tsarin kariya a samar da kebul mai matsakaicin ƙarfin lantarki abu ne mai sauƙi. Duk da haka, idan ba a kula da wasu cikakkun bayanai ba, zai iya haifar da mummunan sakamako ga ingancin kebul.

1. Tef ɗin TagullaTsarin Kariya:

Dole ne tef ɗin jan ƙarfe da ake amfani da shi don kariya ya zama tef ɗin jan ƙarfe mai laushi wanda aka yi masa fenti da kyau ba tare da lahani kamar gefuna masu lanƙwasa ko tsagewa a ɓangarorin biyu ba.Tef ɗin jan ƙarfehakan yana da tauri sosai zai iya lalata shiLayer mai amfani da semiconductive, yayin da tef ɗin da ya yi laushi sosai zai iya lanƙwasa cikin sauƙi. A lokacin naɗewa, yana da mahimmanci a saita kusurwar naɗewa daidai, a sarrafa matsin lamba yadda ya kamata don guje wa matsewa da yawa. Lokacin da aka kunna kebul, rufin yana haifar da zafi kuma yana faɗaɗa kaɗan. Idan tef ɗin jan ƙarfe ya naɗe sosai, yana iya shiga cikin garkuwar rufi ko kuma ya sa tef ɗin ya karye. Ya kamata a yi amfani da kayan laushi azaman madauri a ɓangarorin biyu na reel ɗin ɗaukar na'urar kariya don hana duk wani lalacewa ga tef ɗin jan ƙarfe yayin matakan da ke gaba a cikin aikin. Ya kamata a haɗa haɗin tef ɗin jan ƙarfe da tabo, ba a haɗa shi da tabo ba, kuma ba lallai ne a haɗa shi da matosai, tef ɗin manne, ko wasu hanyoyin da ba na yau da kullun ba.

Idan aka yi amfani da kariyar tef ɗin jan ƙarfe, taɓawa da layin semiconductive zai iya haifar da samuwar oxide saboda saman hulɗa, rage matsin lamba da kuma ninka juriyar hulɗa lokacin da layin kariya na ƙarfe ya fuskanci faɗaɗa zafi ko matsewa da lanƙwasawa. Rashin kyawun hulɗa da faɗaɗa zafi na iya haifar da lalacewa kai tsaye ga waje.Layer mai amfani da semiconductive. Daidaito tsakanin tef ɗin jan ƙarfe da layin semiconductive yana da mahimmanci don tabbatar da ingantaccen tushe. Zafi fiye da kima, sakamakon faɗaɗa zafi, na iya sa tef ɗin jan ƙarfe ya faɗaɗa ya lalace, yana lalata layin semiconductive. A irin waɗannan yanayi, tef ɗin jan ƙarfe da aka haɗa da kyau ko kuma wanda ba a haɗa shi da kyau ba zai iya ɗaukar wutar lantarki daga ƙarshen da ba a gina shi ba zuwa ƙarshen ƙasa, wanda ke haifar da zafi sosai da tsufa cikin sauri na layin semiconductive a wurin da tef ɗin jan ƙarfe ya karye.

2. Tsarin Kariyar Wayar Tagulla:

Lokacin amfani da kariyar waya ta jan ƙarfe mai laushi, naɗe wayoyin jan ƙarfe kai tsaye a saman kariyar waje na iya haifar da naɗewa mai ƙarfi cikin sauƙi, wanda hakan zai iya lalata rufin da kuma haifar da lalacewar kebul. Don magance wannan, ya zama dole a ƙara layuka 1-2 na tef ɗin nailan mai semiconductive a kusa da layin kariyar waje mai semiconductive da aka fitar bayan an fitar da shi.

Kebulan da ke amfani da kariyar waya ta jan ƙarfe mai sassauƙa ba sa fama da samuwar iskar oxygen da ake samu tsakanin layukan tef ɗin jan ƙarfe. Kariyar waya ta jan ƙarfe tana da ƙarancin lanƙwasawa, ƙarancin lalacewar faɗaɗa zafi, da ƙaramin ƙaruwa a cikin juriyar hulɗa, duk waɗannan suna ba da gudummawa ga ingantaccen aikin lantarki, injiniya, da zafi a cikin aikin kebul.

Lokacin Saƙo: Oktoba-27-2023