Takaitaccen Bayani: An yi bayanin ƙa'idar haɗin gwiwa, rarrabuwa, tsari, tsari da kayan aikin silane mai haɗin gwiwa don waya da kebul, kuma an gabatar da wasu halaye na silane mai haɗin gwiwa na polyethylene mai haɗin gwiwa a cikin aikace-aikace da amfani da shi, da kuma abubuwan da ke shafar yanayin haɗin gwiwa na kayan.

Kalmomi Masu Mahimmanci: Haɗin Silane; Haɗin giciye na halitta; Polyethylene; Rufewa; Waya da kebul

Ana amfani da kayan kebul na polyethylene mai haɗin Silane a masana'antar waya da kebul a matsayin kayan rufewa ga kebul na wutar lantarki mai ƙarancin ƙarfin lantarki. Kayan da ake amfani da su wajen kera waya da kebul mai haɗin giciye, da kuma haɗin peroxide da haɗin radiation idan aka kwatanta da kayan aikin masana'antu da ake buƙata abu ne mai sauƙi, mai sauƙin aiki, ƙarancin farashi mai yawa da sauran fa'idodi, ya zama babban kayan da ake amfani da su wajen kera kebul mai haɗin giciye mai ƙarancin ƙarfin lantarki tare da rufin rufi.

1. Ka'idar haɗin kebul na Silane

Akwai manyan hanyoyi guda biyu da ke tattare da yin polyethylene mai haɗin silane: dasawa da kuma haɗawa. A cikin tsarin dasawa, polymer ɗin yana rasa H-atom ɗinsa akan atom ɗin carbon na uku a ƙarƙashin aikin mai farawa kyauta da pyrolysis zuwa cikin radicals masu kyauta, waɗanda ke amsawa da ƙungiyar – CH = CH2 na vinyl silane don samar da polymer da aka dasa wanda ke ɗauke da ƙungiyar trioxysilyl ester. A cikin tsarin haɗawa, polymer da aka dasa da farko ana yin hydrolyzed a gaban ruwa don samar da silanol, kuma – OH yana haɗuwa da ƙungiyar Si-OH da ke maƙwabtaka don samar da haɗin Si-O-Si, don haka yana haɗa macromolecules na polymer.

2. Kayan kebul na Silane da aka haɗa da juna da kuma hanyar samar da kebul ɗinsa

Kamar yadda kuka sani, akwai hanyoyin samar da kebul na silane masu haɗin gwiwa da kebul ɗinsu masu matakai biyu da kuma matakai ɗaya. Bambancin da ke tsakanin hanyar mataki biyu da hanyar mataki ɗaya yana cikin inda ake gudanar da tsarin dasa silane, tsarin dasawa a masana'antar kayan kebul don hanyar mataki biyu, tsarin dasawa a masana'antar kera kebul don hanyar mataki ɗaya. Kayan dasawa polyethylene masu haɗin gwiwa da silane masu matakai biyu waɗanda suka fi girma a kasuwa sun ƙunshi kayan da ake kira A da B, tare da kayan A shine polyethylene da aka dasa tare da kayan silane da B shine babban rukunin catalyst. Sannan ana haɗa tsakiyar rufi a cikin ruwan ɗumi ko tururi.

Akwai wani nau'in silane mai haɗin gwiwa biyu na polyethylene, inda ake samar da kayan A ta wata hanya daban, ta hanyar shigar da vinyl silane kai tsaye cikin polyethylene yayin haɗa shi don samun polyethylene tare da sarƙoƙi masu reshe na silane.

Hanyar mataki ɗaya kuma tana da nau'i biyu, tsarin mataki ɗaya na gargajiya shine nau'ikan kayan masarufi iri-iri bisa ga dabarar da ke cikin rabon tsarin aunawa na musamman, zuwa wani na'urar fitar da kaya ta musamman da aka tsara musamman a mataki ɗaya don kammala dasawa da fitar da tushen rufin kebul, a cikin wannan tsari, babu granulation, babu buƙatar shigar da kayan kebul, ta masana'antar kebul don kammala shi kaɗai. Wannan kayan aikin samar da kebul na silane mai haɗin gwiwa da fasahar tsarawa galibi ana shigo da su ne daga ƙasashen waje kuma yana da tsada.

Wani nau'in kayan rufin polyethylene mai haɗin gwiwa guda ɗaya da masana'antun kayan kebul ke samarwa, duk kayan masarufi ne bisa ga dabarar da ke cikin rabon wata hanya ta musamman ta haɗawa, a naɗe ta a sayar, babu kayan A da B, injin kebul na iya kasancewa kai tsaye a cikin injin fitar da iska don kammala mataki a lokaci guda dasawa da fitar da tsakiyar rufin kebul. Siffa ta musamman ta wannan hanyar ita ce babu buƙatar kayan fitarwa na musamman masu tsada, kamar yadda tsarin dasa silane za a iya kammala shi a cikin na'urar fitar da iska ta PVC ta yau da kullun, kuma hanyar matakai biyu tana kawar da buƙatar haɗa kayan A da B kafin a fitar da iska.

3. Tsarin tsari

Tsarin kebul na polyethylene mai haɗin silane gabaɗaya ya ƙunshi resin kayan tushe, mai farawa, silane, antioxidant, mai hana polymerization, mai haɓaka sinadarai, da sauransu.

(1) Gurashin tushe gabaɗaya resin polyethylene ne mai ƙarancin yawa (LDPE) tare da ma'aunin narkewa (MI) na 2, amma kwanan nan, tare da haɓaka fasahar resin roba da matsin lamba na farashi, an kuma yi amfani da polyethylene mai ƙarancin yawa (LLDPE) ko kuma an yi amfani da shi kaɗan azaman resin tushe don wannan kayan. Gurashin daban-daban galibi suna da tasiri mai mahimmanci akan dasawa da haɗin gwiwa saboda bambance-bambance a cikin tsarin macromolecular na ciki, don haka za a gyara tsarin ta amfani da resin tushe daban-daban ko nau'in resin iri ɗaya daga masana'antun daban-daban.

(2) Mai farawa da aka saba amfani da shi shine diisopropyl peroxide (DCP), mabuɗin shine a fahimci adadin matsalar, ƙarancin da zai iya haifar da dasa silane bai isa ba; yawan da zai iya haifar da haɗin polyethylene, wanda ke rage ruwa, saman tsakiyar rufin da aka fitar yana da kauri, tsarin matsewa mai wahalar matsewa. Ganin cewa adadin mai farawa da aka ƙara ƙanƙanta ne kuma mai laushi, yana da mahimmanci a warwatsa shi daidai gwargwado, don haka gabaɗaya ana haɗa shi tare da silane.

(3) Ana amfani da Silane gabaɗaya a matsayin silane na vinyl wanda ba shi da cikakken silane, gami da vinyl trimethoxysilane (A2171) da vinyl triethoxysilane (A2151), saboda saurin hydrolysis na A2171, don haka zaɓi ƙarin mutane A2171. Hakazalika, akwai matsalar ƙara silane, masana'antun kayan kebul na yanzu suna ƙoƙarin cimma ƙarancin iyaka don rage farashi, saboda silane ana shigo da shi daga ƙasashen waje, farashin ya fi tsada.

(4) Maganin hana tsufa shine tabbatar da daidaiton aikin polyethylene da kebul na hana tsufa da kuma ƙarin maganin hana tsufa a cikin tsarin dasa silane yana da rawar hana amsawar dasawa, don haka tsarin dasawa, ƙara maganin hana tsufa don a yi taka tsantsan, adadin da aka ƙara don la'akari da adadin DCP don dacewa da zaɓin. A cikin tsarin dasawa mai matakai biyu, yawancin maganin hana tsufa za a iya ƙarawa a cikin babban rukunin mai haɓaka, wanda zai iya rage tasirin dasawa. A cikin tsarin dasawa mai matakai ɗaya, maganin hana tsufa yana nan a cikin dukkan tsarin dasawa, don haka zaɓin nau'in da adadin ya fi mahimmanci. Maganin hana tsufa da ake amfani da su galibi sune 1010, 168, 330, da sauransu.

(5) An ƙara mai hana polymerization domin hana wasu dasawa da kuma haɗa hanyoyin haɗin gwiwa, a cikin tsarin dasawa don ƙara wakili mai hana haɗin gwiwa, zai iya rage faruwar haɗin C2C yadda ya kamata, ta haka ne zai inganta sauƙin sarrafawa, ban da haka, ƙarin dasawa a cikin irin wannan yanayi zai kasance kafin hydrolysis na silane akan mai hana polymerization zai iya rage hydrolysis na polyethylene da aka dasa, don inganta kwanciyar hankali na dogon lokaci na kayan dasawa.

(6) Masu ƙara kuzari galibi suna da alaƙa da abubuwan da suka samo asali daga organotin (banda haɗin gwiwa na halitta), wanda aka fi sani da dibutyltin dilaurate (DBDTL), wanda galibi ana ƙara shi a cikin nau'in masterbatch. A cikin tsari mai matakai biyu, ana haɗa kayan da aka dasa (A kayan) da kuma kayan master catalyst (B kayan) daban-daban kuma ana haɗa kayan A da B tare kafin a ƙara su a cikin mai fitarwa don hana haɗin gwiwa kafin kayan A. Idan aka yi amfani da kayan rufin polyethylene mai haɗin gwiwa na silane mai mataki ɗaya, ba a dasa polyethylene da ke cikin kunshin ba tukuna, don haka babu matsalar haɗin gwiwa kafin a dasa kayan, don haka ba a buƙatar a haɗa kayan haɗin gwiwa daban.

Bugu da ƙari, akwai silanes masu haɗaka da ake samu a kasuwa, waɗanda suka haɗa da silane, mai farawa, maganin hana tsufa, wasu man shafawa da magungunan hana jan ƙarfe, kuma galibi ana amfani da su a cikin hanyoyin haɗin silane na mataki ɗaya a cikin masana'antar kebul.

Saboda haka, samar da silane cross-linked polyethylene insulator, wanda abun da ke ciki ba a ɗauka a matsayin mai rikitarwa ba kuma yana samuwa a cikin bayanan da suka dace, amma ya kamata a yi amfani da wasu gyare-gyare don kammalawa, wanda ke buƙatar cikakken fahimtar rawar da sassan ke takawa a cikin tsari da kuma dokar tasirinsu akan aiki da tasirin juna.

A cikin nau'ikan kayan kebul da yawa, ana ɗaukar kayan kebul na silane (ko dai matakai biyu ko mataki ɗaya) a matsayin kawai nau'ikan hanyoyin sinadarai da ke faruwa a cikin fitarwa, wasu nau'ikan kamar kayan kebul na polyvinyl chloride (PVC) da kayan kebul na polyethylene (PE), tsarin granulation na fitarwa tsari ne na haɗakar jiki, koda kuwa kayan kebul na haɗin giciye da radiation, ko a cikin tsarin granulation na fitarwa, ko tsarin extrusion Cable, babu wani tsarin sinadarai da ke faruwa, don haka, idan aka kwatanta, samar da kayan kebul na haɗin giciye da silane da extrusion na rufin kebul, sarrafa tsari ya fi mahimmanci.

4. Tsarin samar da rufin polyethylene mai matakai biyu na silane

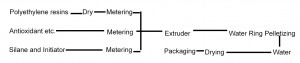

Tsarin samar da rufin polyethylene mai matakai biyu na silane. Ana iya wakiltar kayan ta hanyar Hoto na 1 a taƙaice.

Hoto na 1 Tsarin samar da kayan rufewa na polyethylene mai matakai biyu na silane A

Wasu muhimman abubuwa a cikin tsarin samar da rufin polyethylene mai haɗin silane mai matakai biyu:

(1) Busarwa. Ganin cewa resin polyethylene yana ɗauke da ƙaramin ruwa, idan aka fitar da shi a yanayin zafi mai yawa, ruwan yana amsawa da sauri tare da ƙungiyoyin silyl don samar da haɗin gwiwa, wanda ke rage ruwan narkewar kuma yana samar da haɗin gwiwa kafin a haɗa. Kayan da aka gama kuma yana ɗauke da ruwa bayan sanyaya ruwa, wanda kuma zai iya haifar da haɗin gwiwa kafin a cire shi, kuma dole ne a busar da shi. Domin tabbatar da ingancin bushewar, ana amfani da na'urar busarwa mai zurfi.

(2) Aunawa. Ganin cewa daidaiton tsarin kayan yana da mahimmanci, galibi ana amfani da ma'aunin nauyi na asara da aka shigo da shi daga ƙasashen waje. Ana auna kuma ana ciyar da resin polyethylene da antioxidant ta hanyar tashar ciyar da extruder, yayin da ake allurar silane da mai farawa ta famfon ruwa a cikin ganga na biyu ko na uku na extruder.

(3) Dasawa da fitar da ruwa. An kammala aikin dasa silane a cikin mai fitar da ruwa. Saitin tsarin mai fitar da ruwa, gami da zafin jiki, haɗin sukurori, saurin sukurori da saurin ciyarwa, dole ne su bi ƙa'idar cewa kayan da ke cikin sashin farko na mai fitar da ruwa za a iya narke su gaba ɗaya kuma a gauraya su daidai gwargwado, lokacin da ba a son rugujewar peroxide da wuri ba, kuma cewa kayan da ke cikin sashe na biyu na mai fitar da ruwa dole ne a ruɓe su gaba ɗaya kuma a kammala aikin dasawa. An nuna yanayin zafin sashin mai fitar da ruwa na yau da kullun (LDPE) a cikin Tebur 1.

Tebur 1 Yanayin zafi na yankunan extruder matakai biyu

| Yankin aiki | Yanki na 1 | Yanki na 2 | Yanki na 3 ① | Yanki na 4 | Yanki na 5 |

| Zafin jiki P °C | 140 | 145 | 120 | 160 | 170 |

| Yankin aiki | Yanki na 6 | Yanki na 7 | Yanki na 8 | Yanki na 9 | Baki |

| Zafin jiki °C | 180 | 190 | 195 | 205 | 195 |

① shine inda aka ƙara silane.

Gudun sukurorin extruder yana ƙayyade lokacin zama da tasirin gaurayawan kayan a cikin extruder, idan lokacin zama ya yi gajere, rugujewar peroxide ba ta cika ba; idan lokacin zama ya yi tsayi da yawa, ɗanko na kayan da aka fitar yana ƙaruwa. Gabaɗaya, matsakaicin lokacin zama na granule a cikin extruder ya kamata a sarrafa shi a cikin rugujewar mai farawa na rabin rayuwa sau 5-10. Saurin ciyarwa ba wai kawai yana da wani tasiri ga lokacin zama na kayan ba, har ma da haɗuwa da yanke kayan, zaɓi saurin ciyarwa mai dacewa shima yana da matukar mahimmanci.

(4) Marufi. Ya kamata a naɗe kayan rufewa mai matakai biyu na silane a cikin jakunkunan haɗakar filastik na aluminum a cikin iska kai tsaye don kawar da danshi.

5. Tsarin samar da kayan polyethylene mai rufi da silane mai matakai ɗaya

Kayan rufin polyethylene mai haɗin gwiwa na silane saboda tsarin dasa shi yana cikin masana'antar kebul na fitar da tsakiyar rufin kebul, don haka zafin fitar da rufin kebul ya fi girma fiye da hanyar matakai biyu. Duk da cewa an yi la'akari da tsarin rufin polyethylene mai haɗin gwiwa na silane mai haɗin gwiwa a cikin saurin watsawa na mai farawa da silane da yanke kayan aiki, amma dole ne a tabbatar da tsarin dasawa ta hanyar zafin jiki, wanda shine masana'antar samar da rufin polyethylene mai haɗin gwiwa na silane mai haɗin gwiwa akai-akai yana jaddada mahimmancin zaɓin zafin extrusion daidai, an nuna zafin extrusion gabaɗaya da aka ba da shawarar a cikin Tebur 2.

Tebur 2 Zafin mai fitar da iska mai matakai ɗaya na kowane yanki (naúrar: ℃)

| Yanki | Yanki na 1 | Yanki na 2 | Yanki na 3 | Yanki na 4 | Flange | Kai |

| Zafin jiki | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Wannan yana ɗaya daga cikin raunin tsarin polyethylene mai haɗin silane mai mataki ɗaya, wanda gabaɗaya ba a buƙatar shi lokacin fitar da kebul a matakai biyu.

6. Kayan aikin samarwa

Kayan aikin samarwa muhimmin garanti ne na sarrafa tsari. Samar da kebul na silane mai haɗin gwiwa yana buƙatar babban matakin daidaiton sarrafa tsari, don haka zaɓin kayan aikin samarwa yana da matuƙar muhimmanci.

Samar da kayan rufin polyethylene mai matakai biyu na silane. Kayan aikin samar da kayan aiki, wanda a halin yanzu yake da mafi yawan kayan aikin haɗin gwiwa na isotropic a cikin gida tare da nauyin da ba shi da nauyi da aka shigo da shi, irin waɗannan na'urori na iya biyan buƙatun daidaiton sarrafa tsari, zaɓin tsayi da diamita na kayan aikin haɗin gwiwa na sukurori don tabbatar da cewa lokacin zama na kayan aiki ya yi daidai, zaɓin kayan aikin haɗin gwiwa na marasa nauyi da aka shigo da su don tabbatar da daidaiton kayan aikin. Tabbas akwai cikakkun bayanai da yawa game da kayan aikin da ya kamata a ba su cikakken kulawa.

Kamar yadda aka ambata a baya, kayan aikin samar da kebul na silane masu haɗin gwiwa guda ɗaya a cikin masana'antar kebul ana shigo da su daga ƙasashen waje, masu tsada, masu kera kayan aiki na cikin gida ba su da irin wannan kayan aikin samarwa, dalilin shine rashin haɗin gwiwa tsakanin masana'antun kayan aiki da masu binciken dabara da tsari.

7. Silane na halitta giciye-linked polyethylene rufi abu

Kayan rufin polyethylene na Silane da aka ƙera a cikin 'yan shekarun nan za a iya haɗa su a cikin yanayi na halitta cikin 'yan kwanaki, ba tare da tururi ko nutsewa cikin ruwa mai ɗumi ba. Idan aka kwatanta da hanyar haɗin giciye na silane na gargajiya, wannan kayan zai iya rage tsarin samarwa ga masana'antun kebul, yana ƙara rage farashin samarwa da ƙara ingancin samarwa. Masana'antun kebul suna ƙara fahimtar rufin polyethylene na Silane kuma suna amfani da shi.

A cikin 'yan shekarun nan, rufin polyethylene na silane na cikin gida ya girma kuma an samar da shi da adadi mai yawa, tare da wasu fa'idodi a farashi idan aka kwatanta da kayan da aka shigo da su daga waje.

7. 1 Ra'ayoyin ƙira don rufin polyethylene mai alaƙa da silane ta halitta

Ana samar da rufin polyethylene na Silane na halitta mai haɗin giciye a cikin tsari mai matakai biyu, tare da tsari iri ɗaya wanda ya ƙunshi resin tushe, mai farawa, silane, antioxidant, mai hana polymerization da mai haɓaka. Tsarin rufin polyethylene na silane na halitta mai haɗin giciye ya dogara ne akan ƙara yawan dasa silane na kayan A da zaɓar mai haɓaka mai inganci fiye da rufin polyethylene mai haɗin giciye na silane na ruwan dumi. Amfani da kayan A tare da babban saurin dasa silane tare da mai haɓaka mai inganci zai ba da damar rufin polyethylene mai haɗin giciye na silane don haɗuwa da sauri ko da a yanayin zafi mai ƙarancin zafi da rashin isasshen danshi.

Ana haɗa kayan A-kayan da ake amfani da su wajen hana silane da aka shigo da su ta hanyar amfani da sinadarai masu alaƙa da polyethylene ta hanyar amfani da copolymerisation, inda za a iya sarrafa yawan silane a babban mataki, yayin da samar da kayan A masu yawan dasawa ta hanyar dasa silane yana da wahala. Ya kamata a bambanta resin tushe, mai farawa da silane da ake amfani da su a cikin girke-girke kuma a daidaita su dangane da iri-iri da ƙari.

Zaɓin juriya da daidaita yawanta suma suna da mahimmanci, domin ƙaruwar saurin dasa silane ba makawa yana haifar da ƙarin halayen haɗin gwiwa na CC. Domin inganta sauƙin sarrafawa da yanayin saman kayan A don fitar da kebul na gaba, ana buƙatar adadin mai hana polymerization mai dacewa don hana haɗin gwiwa na CC da haɗin gwiwa na gaba yadda ya kamata.

Bugu da ƙari, masu haɓaka sinadarai suna taka muhimmiyar rawa wajen ƙara yawan haɗin gwiwa kuma ya kamata a zaɓe su a matsayin masu haɓaka sinadarai waɗanda ke ɗauke da abubuwan da ba su da ƙarfe.

7. 2 Lokacin haɗin gwiwa na silane na rufin polyethylene da aka haɗa ta hanyar halitta

Lokacin da ake buƙata don kammala haɗin gwiwar silane na halitta mai haɗa polyethylene a yanayinsa na halitta ya dogara ne akan zafin jiki, danshi da kauri na layin kariya. Mafi girman zafin jiki da danshi, haka nan kauri na layin kariya ya yi laushi, gajeriyar lokacin haɗin gwiwa da ake buƙata, da kuma tsawon akasin haka. Ganin cewa zafin jiki da danshi sun bambanta daga yanki zuwa yanki da kuma daga yanayi zuwa yanayi, ko da a wuri ɗaya kuma a lokaci guda, zafin jiki da danshi na yau da gobe za su bambanta. Saboda haka, yayin amfani da kayan, mai amfani ya kamata ya ƙayyade lokacin haɗin gwiwa bisa ga zafin jiki da danshi na gida da na yanzu, da kuma ƙayyadaddun kebul da kauri na layin kariya.

Lokacin Saƙo: Agusta-13-2022